What is H-20/HS-20 Loading?

AASHTO’s H-20 and HS-20 are live load ratings applied to the design of bridges or other suspended items (e.g. lids for concrete vaults).

What’s the Difference Between H-20 and HS-20?

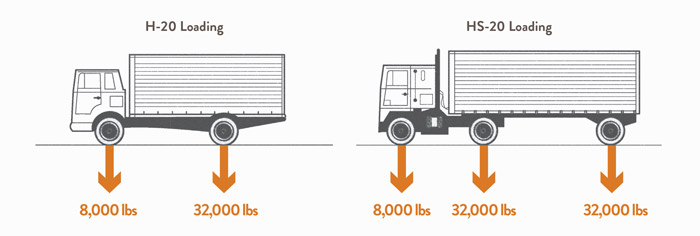

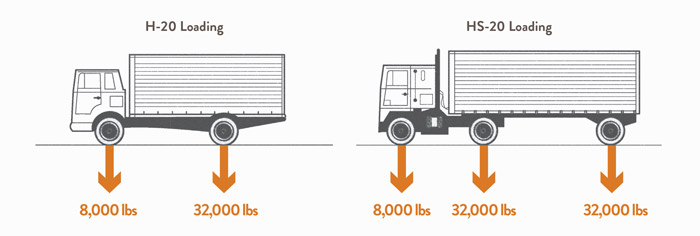

The difference between an H-20 and HS-20 is an H series truck has two loaded axles, one for the drive axle and one for the trailer, and an HS series truck has more than two loaded axles, one for the drive axle and more than one for the trailer.

Do Pavers Meet AASHTO H-20/HS-20 Loading Design Specifications?

A common question posed by design professionals is the ability of pavers to withstand fire truck loading and meet AASHTO’s HS-20 loading specifications. This is an important design consideration due to the extremely high axle weights that fire trucks exert; in fact, certain states (California for example) have created fire truck exemptions whereby the maximum allowable weight of a fire truck can exceed the Department of Transportation allowable weight restrictions. Every paver in the Belgard product line is manufactured to exceed H-20/HS-20 loading design standards.

Simply put, Belgard pavers are on average 40 times stronger than required to withstand the surface pressure that would be exerted under the most extreme conditions, and therefore exceed the requirements of H-20 and HS-20 loading if the pavement has been properly designed for the site conditions including traffic loading and subgrade strength.

Using a conservative contact area on the bottom of the wheel of 8 inches square, the pressure exerted by each front wheel is 187.5 psi (12,000 pounds/64 square inches). Any concrete paver offered under the Belgard line is made in accordance with ASTM C936, which calls for an average compressive strength of 8,000 psi with no individual unit being less than 7,200 psi.

See Designing the Pavement System for more details. For more design specifications on fire truck loading download our Structural Design of Roads for Fire Trucks PDF.