DESIGN SOLUTIONS

Designing the Pavement System

The Science Behind the Structural Design

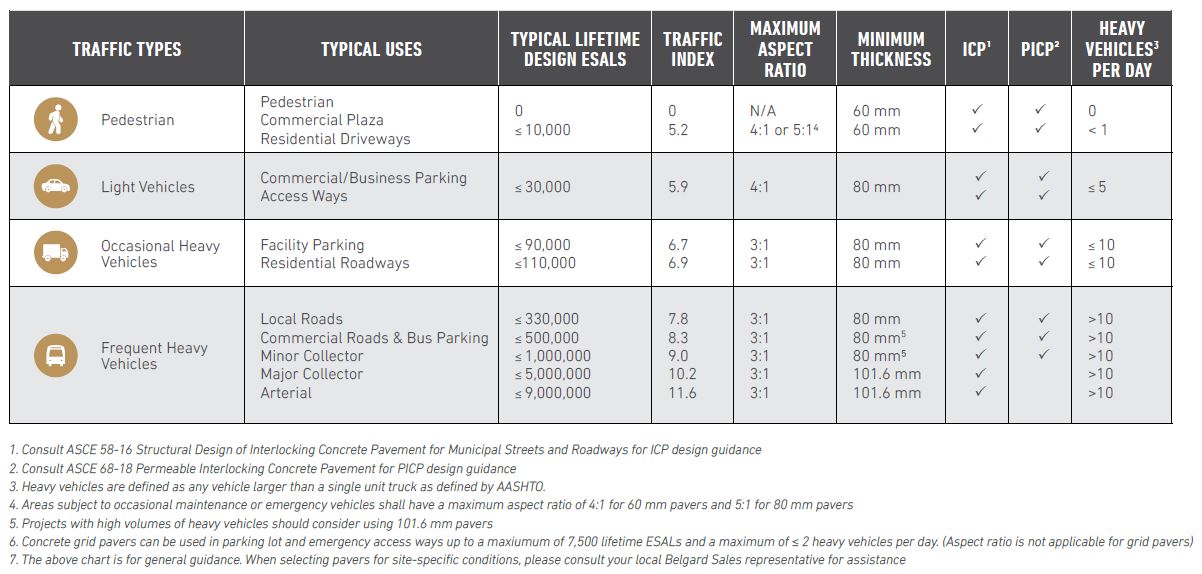

Interlocking concrete pavement systems, including permeable interlocking concrete pavement (PICP), are versatile and durable pavement systems which can be used for a variety of pedestrian and vehicular applications. The success of any pavement is dependent on proper design, construction, and maintenance. Fortunately, ASCE has published design standards for both ICP and PICP. ASCE 58-16 is the latest edition of the ICP standard for structural design, and ASCE 68-18 is the recently published standard for PICP for both structural and hydrologic design.

Designers can utilize these ASCE design standards to calculate the minimum pavement section to withstand the damage of repetitive dynamic loading from traffic over the pavement’s lifespan based on the native soil’s bearing capacity. Equivalent single axle loads (ESALs) are used to determine the pavement damage done by each vehicle type compared to the damage caused by an 18,000-pound axle load. For example, passenger cars have a vehicle load factor of 0.0004 (it takes 2,500 cars to equal one ESAL) while a fully loaded fire truck can be as many as 10 ESALs.

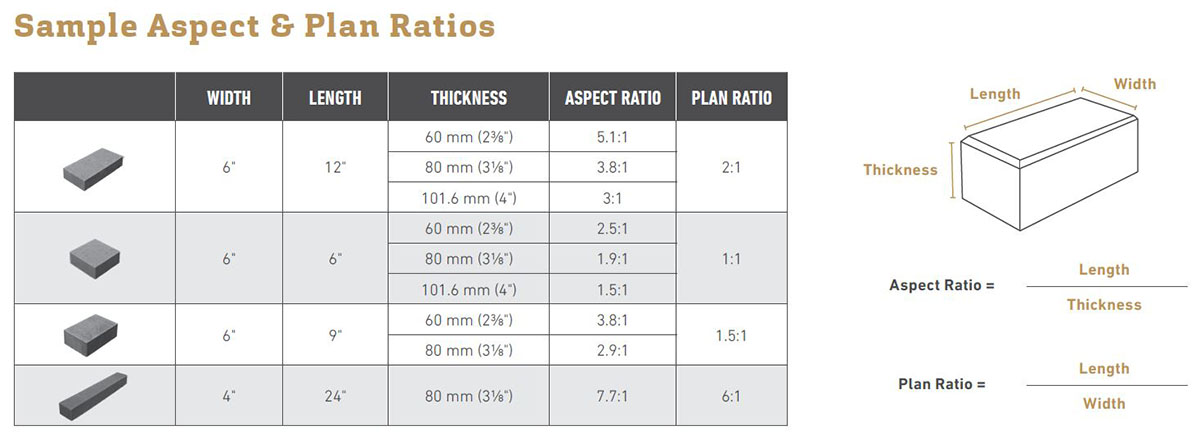

Once the traffic loading is calculated, paver thickness and aspect ratio must be selected to maximize performance and durability. The heavier the expected traffic, the thicker the paver needs to be to prevent rotation. Key factors for design of both ICPs and PICPs are subgrade strength, thickness of the base materials, paver thickness, paver aspect ratio, and laying pattern.

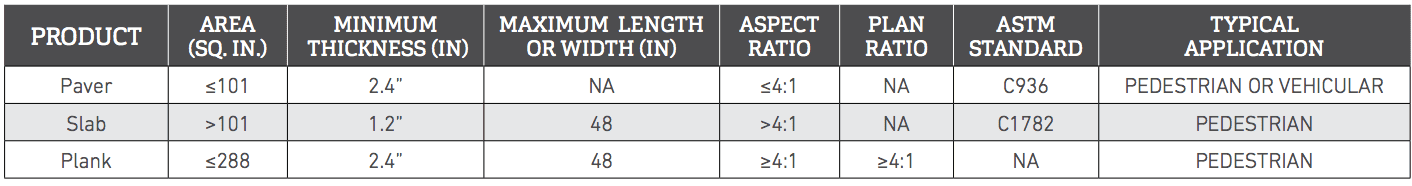

Is the Concrete Segmental Product a Paver, Slab or Plank?

Paver shape and thickness must be selected based on the application. Most long planks and large slabs are not suitable for vehicular applications. Concrete segmental units should be evaluated based on a variety of site-specific conditions. The project pavement engineer should confirm that the product can meet expected performance for vehicular loading conditions.

NOTE: Reference the Canadian Standards Association A231.1 and A231.2 for unit concrete definitions applicable in Canada.

Paver Application Recommendations

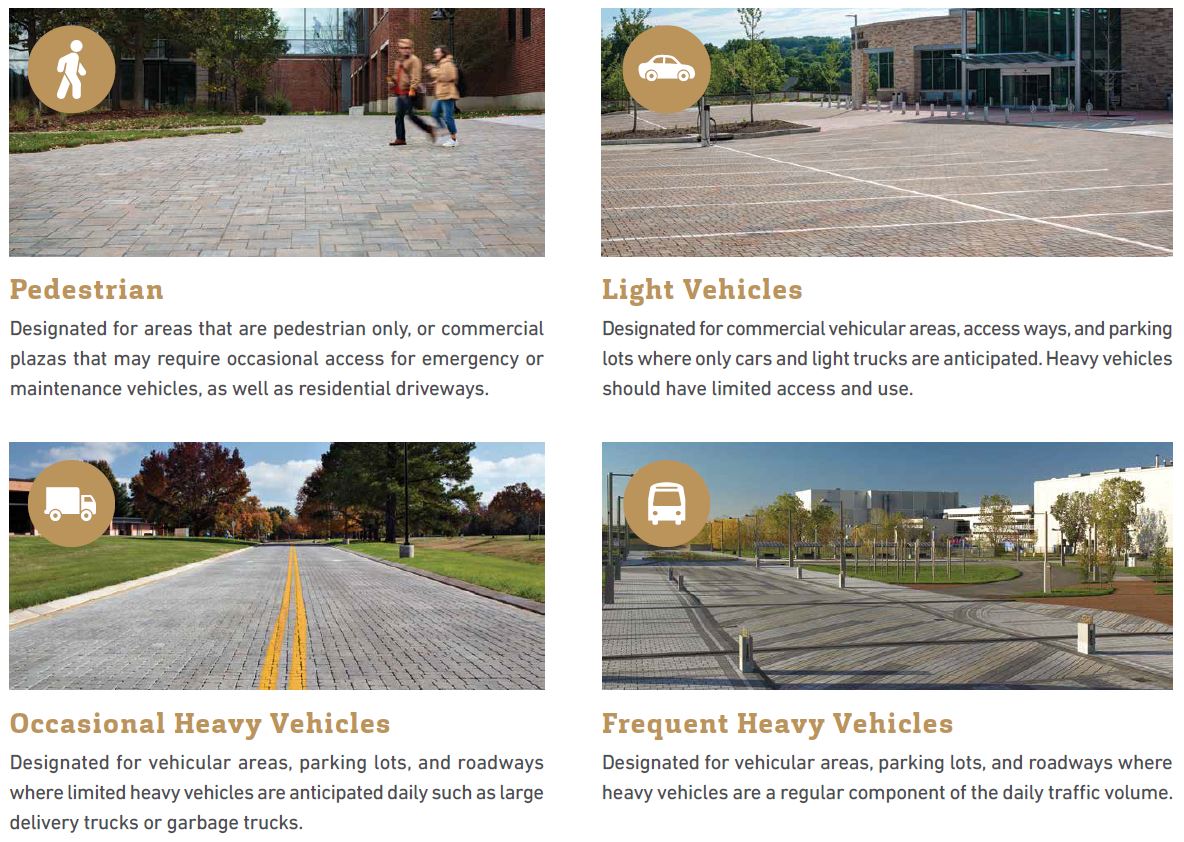

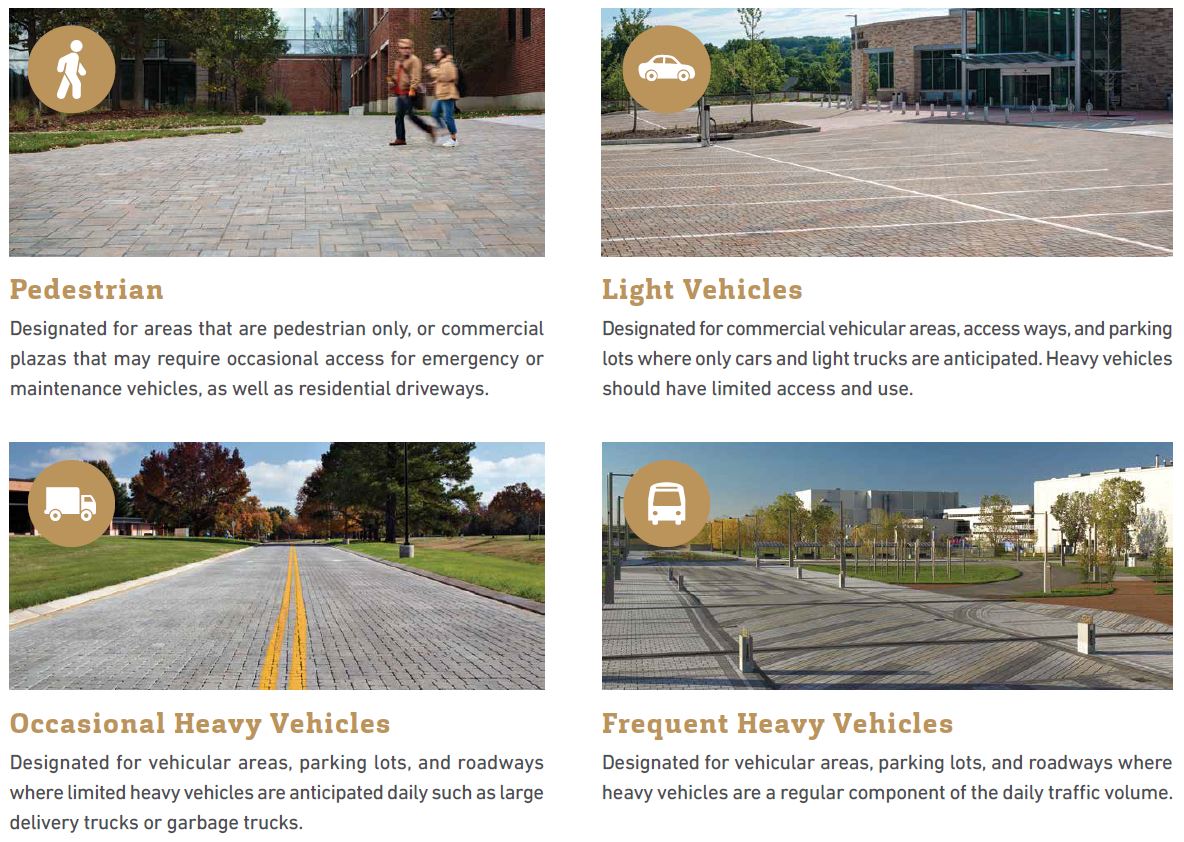

The following chart contains general recommendations for both interlocking and permeable concrete pavement systems including minimum thickness and maximum aspect ratio for several traffic types and uses. While this chart provides general recommendations, a pavement design professional should confirm that the product selected meets local standards and site-specific traffic and use conditions.